Using Polarized Filtration, LED Disinfection System to Improve IAQ

A patent-pending technology can offer the same effectiveness of a high-efficiency filter in a smaller profile. The winner of the 2020 AHR Expo Innovation Awards’ indoor air quality category is a turn-key solution that combines class leading IAQ technologies into a single 1-inch low-profile design.

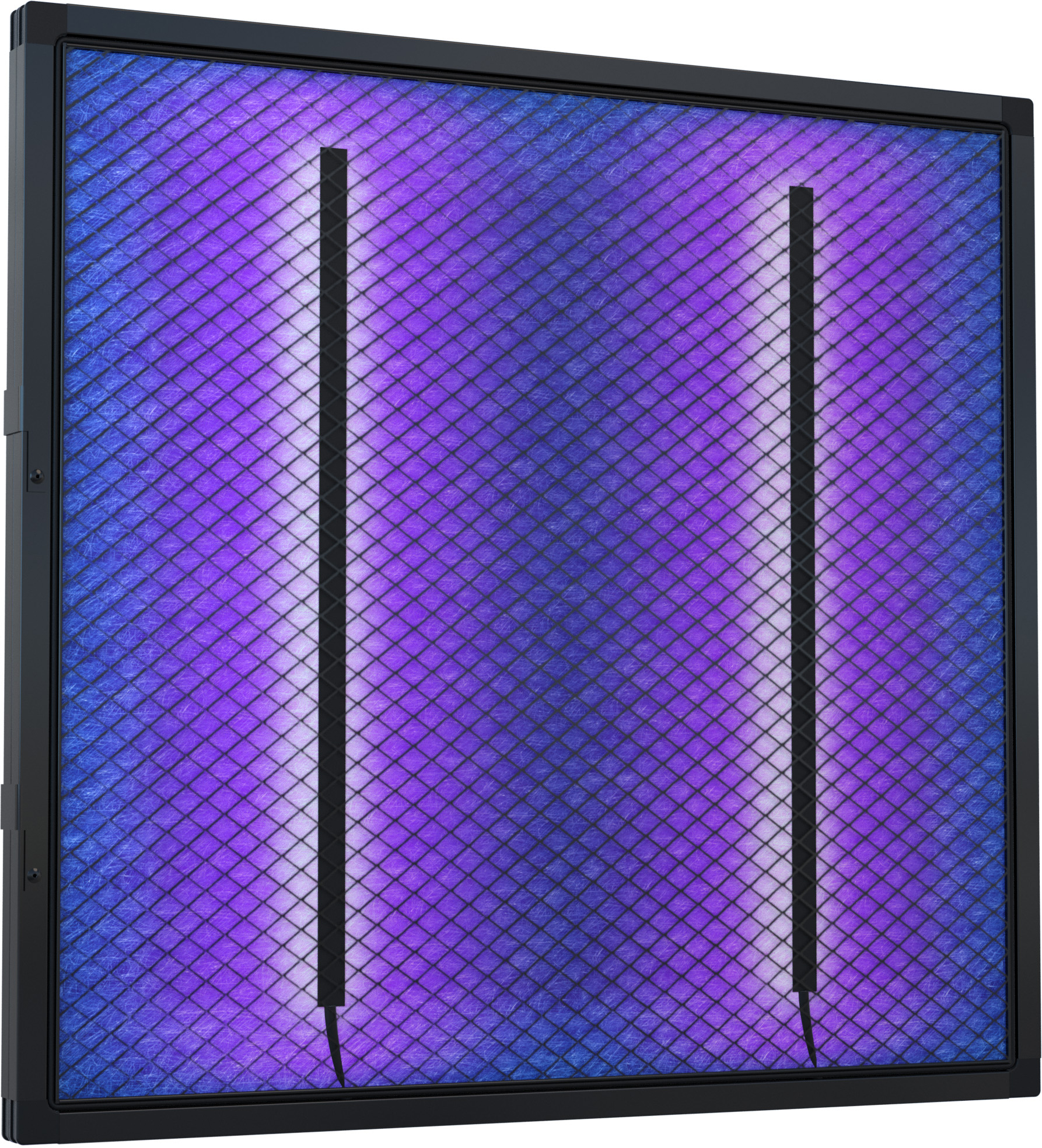

Fresh-Aire UV’s (Booth 5853) Purity Low Profile LED 1" Polarized Filter/LED Disinfection System (PLP-LED) is the first 3-stage 1-inch polarized HVAC filtration system to incorporate Mini-LED technology. It captures 97% of particles to 0.3 microns. The product is debuting at the Show.

Before the development of this filtration product, Fresh-Aire UV addressed “two-thirds of the IAQ pie” with a line of IAQ products including ultraviolet and carbon-type systems, said Aaron Engel, the company’s vice-president business development. Now the company offers a full-suite of IAQ products, he said.

“Although there are high-efficiency filters on the market and costly electronic air cleaners that require extensive duct modifications for installation, the patent pending PLP-LED 1” Polarized Filter is the first product of its kind to offer the effectiveness of a high-efficiency filter in a low-static pressure 1-inch design. The easy-to-install high-efficiency system effectively captures sub-micron particulates, disinfects and reduces odors and volatile organic compounds (VOCs),” said Engel.

Because conventional filters are designed to remove particulates from the air, mold and other contaminations grow on the filter media, said Engel.

“PLP-LED delivers high-efficiency sub-micron particulate removal without the static pressure that is common for conventional pleated filters. This benefits the end-user with not only improved airflow, but with a filter that is continually being disinfected on an ongoing basis eliminating odors and contamination,” he said.

How Does It Work?

The product’s innovation is based on the benefits of non-ozone photocatalytic polarization.

“Where conventional mechanical filtration relies on high-static causing media to deliver greater particulate impingement, the polarizing ability of PLP-LED uses less restrictive media. The photocatalytic polarizing charge attracts and conglomerates particulates and reduces odors and VOCs allowing them to be easily captured and oxidized without the efficiency-robbing static pressure from conventional filters,” said Engel.

Because filters are often the source of mold and other contamination, they can cause odors and biological blow-off. Treating the glass media with anti-microbial coatings naturally helps prevent growth and contamination, he said.

“The PLP-LED employs Fresh-Aire UVs award-winning LED disinfecting array to further help maintain a filter free from mold and biofilm. Where odors may often be contributed to a ‘dirty’ filter, the anti-microbial features of the PLP-LED help maintain a filter that is safer to use by the end-user and safer to replace by the technician,” he said.

The PLP-LED is a 3-stage 1-inch polarized HVAC filtration system that incorporates Fresh-Aire UV’s mini-LED technology. Engel broke it down to three stages. The first stage is the system offers high-efficiency filtration capturing 97% of particles down to 0.3 microns (.00001 inches) in size while using advanced Nanotech antimicrobial UV reactive media and disinfecting LED array for maximum particulate removal and surface disinfection, which is the second stage. The third stage is UV Reactive media is treated with an advanced photocatalytic coating designed to reduce airborne odors and VOCs, according to Engel.

“The polarized UV reactive media attracts particulates allowing sub-micron sized contaminants to be easily captured. The polarizing effect delivers high-efficiency filtration with low static-pressure,” he said. “The combination LED disinfecting array and anti-microbial coatings offer additional surface disinfection preventing potential microbial growth, fouling and biological blow-off. The advanced photocatalytic process further reduces problematic airborne odors and VOCs.”

The polarizing media is designed to be replaced every four to six months in order to maintain optimum efficiency. Engel said replacement takes minutes.

Designed to easily fit into conventional filter-tracks and grills and powered through a 24V connection or optional plug-in transformer, the system requires no ductwork modifications. It is available in popular filter sizes.

Behind the Product

Fresh-Aire UV talked with end-users, installers, wholesalers, engineers and others to develop this product over three years. With advancements in LED technology, the engineering team created the product to help check off requirements on a customer “wish-list,” said Engel.

In 2005, Fresh-Aire UV brought a UVC lighting with a 1-inch filter to market, which was designed to address particulate removal and surface disinfection, he said. “The challenges at the time were the limitations in technology and space constraints.

Engel said the issue with traditional UV lamps is their large size is not conducive for designing a 1-inch filter in addition to the power draw and heat load—especially in small, tight places. Over the past 10 years, LED technology has improved UV-disinfecting LEDs’ effectiveness, output and lowered costs. Fresh-Aire UV’s first polarized filter with embedded LED disinfecting arrays manages the different technologies that would be packaged in a low-profile design.

In 2016, the company engaged with leading LED technology experts and secured research laboratories for testing, said Engel. He said the lab testing was vital in substantiating the embedded LED array’s effectiveness to show the necessary microbial reduction, which compliments the advantages of the polarized filtration media.

“The engineering and design team were able to design a prototype polarized filtration system that far surpassed expectations with an all-new 1-inch high-efficiency filter design allowing for low static pressure combined with LED disinfection and photocatalytic coatings.”

“The proprietary anti-microbial nano-photocatalytic coating had to also be engineered into the media as to allow sufficient contact surface area and performances. The PLP-LED had to show substantial effectiveness above typical particulate removal to substantiate the new improved features including the LED arrays for microbial disinfection and photocatalytic coatings for odor and VOC reduction,” said Engel. The company has submitted a patent application.

For additional coverage of AHR Expo, visit ASHRAE Journal’s AHR Today web page.